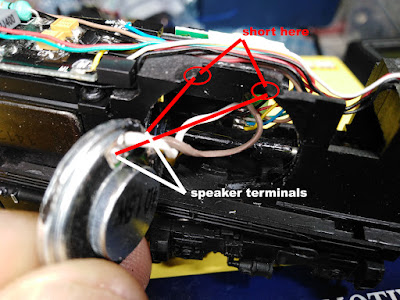

The ESU V5 sound decoders cannot have the audio shorted at any point when power from the track is applied. Most of the files we supply are tidied-up files from ESU and are tested before dispatch, that is, they are run in a decoder tester with a large speaker, so we know they work at dispatch.

A customer returned this locomotive with the decoder and speaker installed, as we could not diagnose the issue over the phone. The customer retested the locomotive with the DC plug, which ruled out a locomotive issue as the engine ran smoothly.

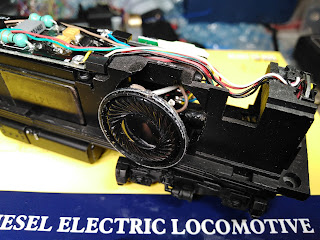

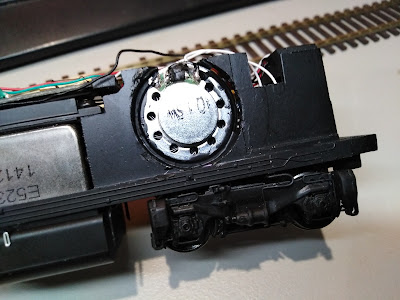

As shown, the speaker mount was designed to have the speaker face into the chassis; a final trick to get the best volume is to apply a piece of brown packaging tape across the back before reinstallation. This seals the enclosure in a superior manner to the locomotive wall and will increase speaker fidelity in operation.

I chose to seal the gap between the rim of the speaker and the frame using liquid insulation available at Jaycar. It is expensive and prone to drying up, so as you use it, wind up the used portion of the tube at all times, fit the cap and store it nose down. Now does it make a great difference, hard to say, but it will cannot hurt.

Note: The ESU 23 mm 4-ohm speaker is the only one that will fit this application. Our micro-speaker is a good substitute if not available.

As the engine and decoder were supplied by the MRRC, this cost $75 for a new decoder repair and installation.

|

Correct installation and remember the packaging tape across the back of the speaker |