This blog cover the installation of sound into the Powerline T class and a SoundTraxx Econami - intermediate level

The shell is secured using four [4] self tapping screws located on the underside of the locomotive at each end. These are very short and may not grip on reinstallation, so be careful when tightening. Next, remove both coupler and pockets. We recommend the couplers be replaced, they are a low quality copy of the Kadee, whisker type recommended.

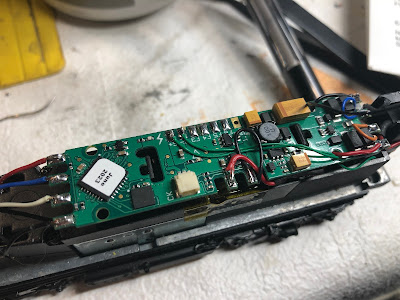

The board used is a standard Atlas DA-SR type and secured with the clips inserted through the decoder. Photo graph all the wiring before proceeding.

Both the markers are wired to the front and rear headlights alternatively and we will split these at installation. The wiring colours are all over the place so just identify each one removed which is done by sliding back the plastic clips and removing the wire. Once done arrange so you know who is who especially the track pickups.

Extend the motor wires by about 30 mm for reinstallation.

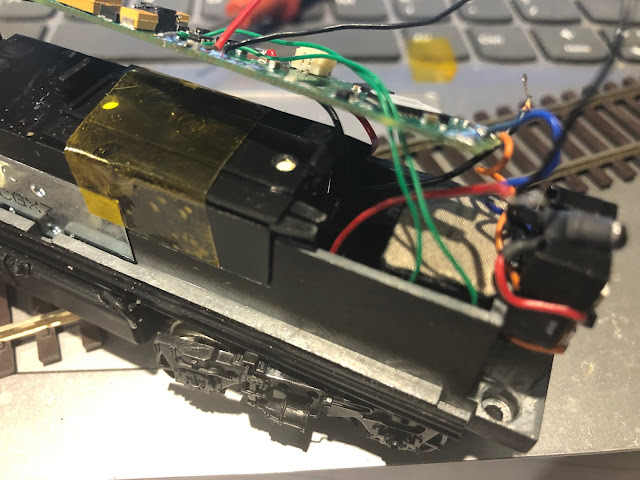

Locate the front of the decoder as per the diagram supplied with the decoder after tinning all the front and rear lugs along with the speakers and FX3/4.

Remove the mounting clip using the two screws into the chassis and relocate so the wire retainers are just over the rear edge of the current mounting location. Secure using ACC or Kaptron tape.

|

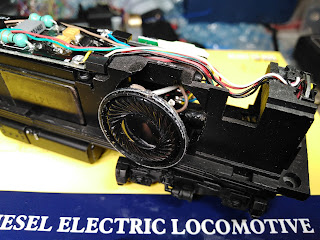

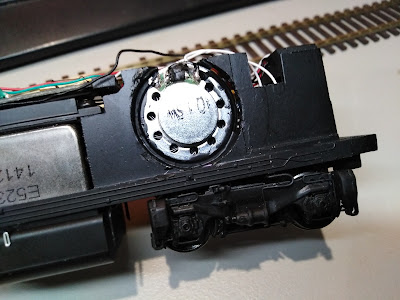

Mounting clip and speaker refitted |

Next solder the speakers wires onto the speaker allowing about 60 mm for trimming at installation. Secure the speaker in its location in the pocket at the rear of the chassis near the rear lighting.

Buzz the track wire to confirm which ones are the track wires, there are NO mistakes here.

Solder all the wires to there respective lugs including the front and rear markers FX3/4 - Front/ Rear markers. Note how on the rear wiring the unused mounting holes are used to keep the wires in place for reassembly

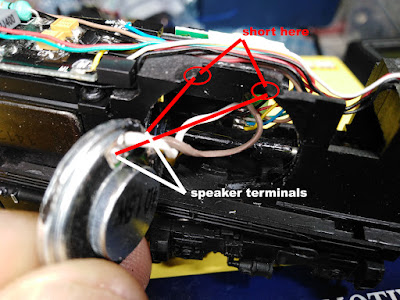

Check you have 8 ohms across the speaker attachment points after soldering the wires.

Place your locomotive and connect the PowerCab to one track after setting it to display to amps. Tap the other wire on the track and if the current runs past 0.04 amps STOP there is something wrong.

With the Soundtraxx Econami decoder shown a blue status light will shown that all is OK. Configure the decoder to your personal taste, we used JMRI as most sound decoders are well beyond hand programming.

Test is all is OK reinstall the shell in the reverse order. We found it harder to install than remove and dressed both end to remove every burr and finally it slipped back but I cannot confirm why.

With tuning it will run smoothy but mak

.jpg)